Manufacture of food supplements: support, galenic solutions and packaging

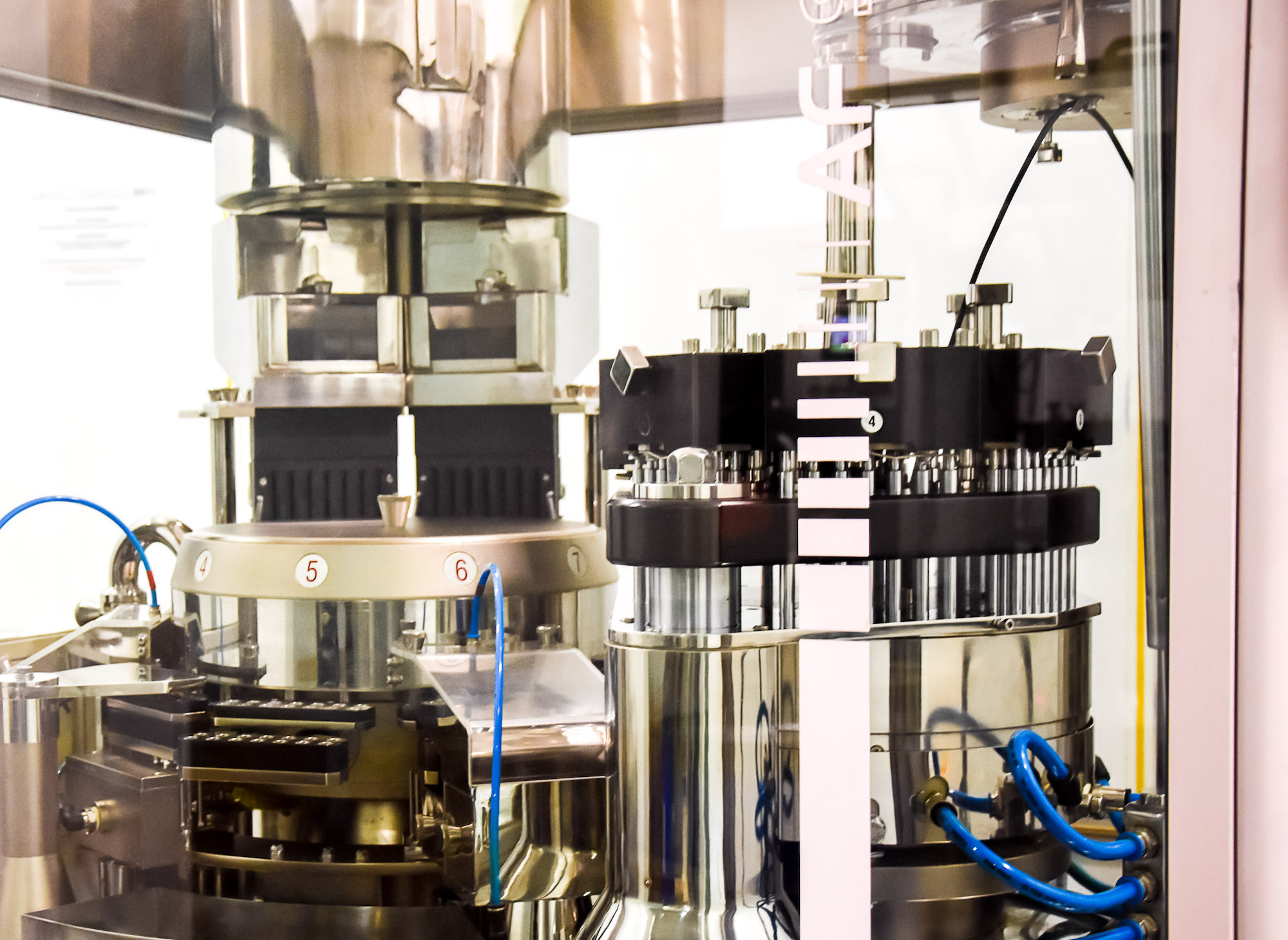

Located in Vendargues close to the Mediterranean sea, the Novapharm site extends across 1,400 m2. It has new production equipment (24 manufacturing machines and packaging lines), in compliance with HACCP and ECOCERT certifications, and adaptable to the needs our clients so as to be as responsive as possible.

Our experts accompany you in your projects to develop food supplements providing either a full service or part service.

1. Project

Feasibility study. Sourcing of raw materials depending on your needs. Planning.

2. Formula

Formulation development proposal with choice of the adapted form. Production test.

3. Commercial offer

Study of the project amount (development, production, packaging, delivery, marketing, etc.).

4. Development

Execution of bench tests and pilot tests with readjustment of the formula if necessary.

5. Packaging

Your choice of packaging (pill box, vial, blister pack, etc.) and customisation upon request.

6. Registration

Administrative assistance in the registration of your food supplement prior to its marketing.

7. Production & Quality

Production in accordance with the specifications and formula validated under quality control. Analysis of the finished product prior to release by the Quality department.

8. Delivery

Dispatch of your production to the requested location prior to the final stage of marketing.

Our galenic solutions

Within its laboratories, Novapharm has a comprehensive, new, production tool adapted to both small (from 500 units) and large production batches in different organic or conventional galenic forms.

2 PACKAGING LINES (CAPSULES/TABLETS):

- An automatic packaging line for clip or screw tops, labelling, marking (more than 1,000 units),

- A small production batch packaging line (less than 1,000 units).

NEW FEATURES:

- Small production batch labellers (two stick sizes: 2.5 and 4.5 cm),

- A powder container packaging line from 30 g.

OTHER POSSIBLE PACKAGING:

- Automatic cartoner

- Batcher

- Sleeve fitting

- Blister sleeve insertion possible with partners

Novapharm has 20 years’ experience in the design and manufacture of liquid food supplements in diluted, concentrated or syrup formulas.

Amongst our services, we have the in-house expertise to produce all types of aqueous, glycerine, oily or alcoholic formula (not ATEX). Our R&D teams particularly enjoy working on the taste of your products so as to offer you the best taste sensation possible.

From monodoses to litres, including sticks from this year, we are able to offer you a wide range of possible packaging.

We have:

- Several atmospheric vats to create your mixtures,

- Two aqueous extraction vats for decoctions,

- A 500-litre heated tyndallisation vat to create organic, preservative-free liquids (since 2020).

FOR MONODOSES:

- 10-ml unicadose line,

- 10 to 100-ml line in spray form, single-dose.

OTHER POSSIBLE PACKAGING:

- A labeller for liquid and paste products has been available, in 2.5 cm and 4.5 cm format for small production batches, since 2020

(from 10,000 sticks),

- Sleeving,

- In the form of berlingos.

Microencapsulation refers to all of the techniques enabling individualised particles to be obtained.

The micro-particles obtained can be divided into two groups:

– Microcapsules comprised of a solid envelope containing a liquid, solid, or paste-type substance. Each microcapsule behaves like a reservoir.

– Microspheres comprised of a continuous network of support material in which the substance to be encapsulated is dispersed. Each microcapsule behaves like a matrix.

The innovative Novacaps® process developed by Novapharm is an original combination of these two systems. It consists of transforming an active liquid (oily or aqueous) or solid (solubilised or dispersed in a suitable solvent) so as to obtain a free-flowing powder.

- Essential oils: (orange, eucalyptus, oregano, lavender, etc.)

- Vegetable oils: (borage, evening primrose, blackcurrant seed, argan, etc.)

- Oils of marine origin: (fish, krill, micro-algae, etc.)

- Sensitive molecules: (vitamins, co-factors, pigments, enzymes, etc.)

Do you have a project?

Would you like to develop a food supplement formula? Would you like to find out more about our generic brand range?